Magcat® Textured Catalyst

Our industry-leading Magcat® Textured steam reforming catalysts are designed to improve heat transfer coefficient (HTC) provide high intrinsic strength and lower pressure drop across the gas purifying and separating processes.

These properties deliver performance benefits at constant plant rate including lower pressure drop; lower tube skin temperatures; and reduced reforming firing. This gives an overall increase in operation efficiency at the given operating conditions, reducing energy costs and footprint of the reformer.

- Innovation

- Flexible Manufacturing

- Supply Chain Stability

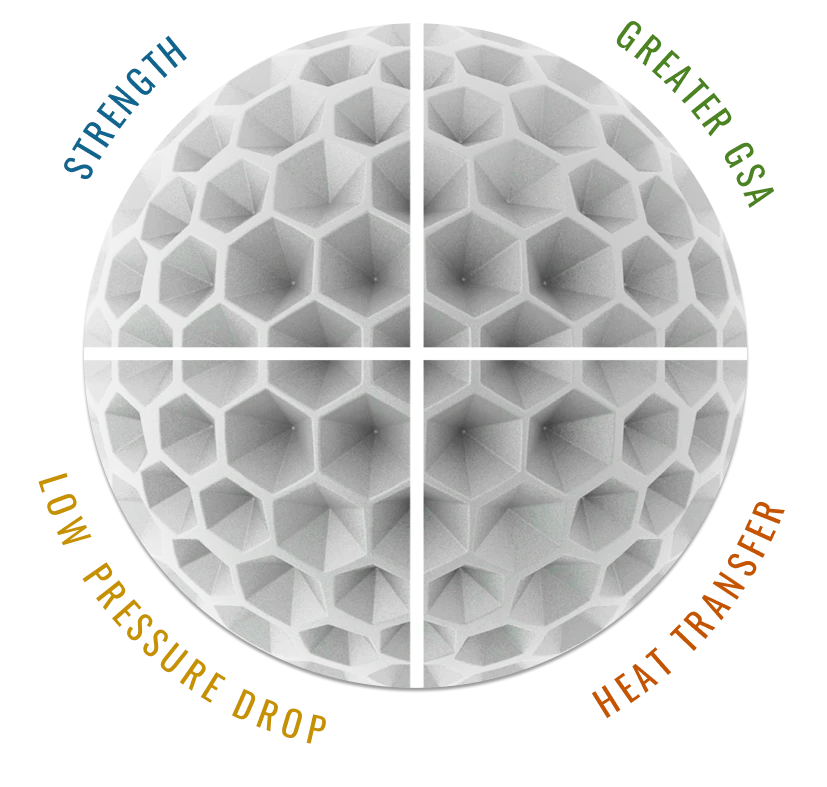

Designed for greater strength, GSA and heat transfer

Formed utilising polymer ceramic technology rather than the traditional pressure method, this groundbreaking technology is bringing huge efficiency improvements.

The material and shape – with a golf ball like surface - innovates in the areas of surface area, strength, catalytic activity, porosity and heat transfer. The spheres deliver excellent performance in tubular SMR reformers, including 35% increase in strength while improving porosity and pore size, increasing the permeation of the gas into the carrier.

Strength

- Magcat® > 300 lb/ft (+50% higher than competitor*)

- Higher Attrition Resistance

- Stronger pellets that pack better

Low Pressure Drop

- More methane processed

- Reduction in operating costs

- Greater strength reduces pressure drop increase over life of catalyst

Greater GSA

- +30% improvement in active surface area

- More sub-surface area available for chemical reaction

- Optimised Nickel loading and placement avoiding wastage

Heat Transfer

- Maximum Heat Transfer

- Uniform packing reduces thermal stress on the reactor tube

- Extending tube life span therefore reducing cost of re-tubing

Our Queen’s Award for Innovation

We were given a Queen’s Award for Enterprise for the development of Magcat® Textured steam reforming catalysts, having tested the use of over 40 shapes, materials and designs in our lab to find the best solution.

The outcome concluded that a textured shape gave a 30% increase in geometric surface area over the other offerings in the market, and our in-house bespoke production process at our automated forming, firing and dipping facility can now manufacture over 6 tons of catalyst product per day.

Energy efficiency, lower CO2 emissions, increased hydrogen production, and extended tube life are some of the advantages of next generation spherical catalysts.

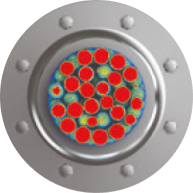

Reduction in tube wall temperature

Increase in tube life

Heat Transfer

Magcat®’s Ideal gas flow patterns increase heat transfer rates from the tube wall, which in turn increases reforming capability, and reduces tube wall temperatures.

The average reduction in tube wall temperature is 10°C, which in turn can deliver a 40% increase in tube life.

Heating & Cooling of Tubes

Traditionally when hot tubes expand and cool (contract) catalysts reorder, and the catalyst levels drop causing increases in pressure drop. Magcat® spheres respond differently, as those in the central core barely move from the original position.

Magcat® 27mm Holed Sphere

Competitors Cylindrical Catalyst

Products

Pre-Reforming

Magcat® PR

UNICAT's Magcat® PR pre-reformer catalyst is made using UNICAT proprietary Gel casting Ceramic Technology enabling highly porous and tailored pore structure which allows higher diffusion of reactants to catalyst active sites resulting in high catalytic activity. It also has a special promoter making it more resistant to carbon deposition. It is designed for medium to heavy hydrocarbon service applications where low pressure drop and low temperature activity for reforming reactions is required. It can be supplied in a prereduced, stabilized form, and it is made for easy start-up procedures. It has high tolerance to poisons, thermal stability, crush strength, and Ni surface area.

Secondary Reforming

Magcat® OTS

Magcat® OTS is part of the series of steam reforming catalysts that are used for the conversion of off gas, natural gas and LPG feeds in steam reforming plants.

Magcat® OTS - textured catalyst is designed for use in the outlet section of a reformer tube where processing methane rich feeds. The use of this non-promoted, textured catalyst allows nickel crystallites to be evenly distributed and highly active for steam reforming and close ATE.

Primary Reforming

Magcat® ITS

Magcat® ITS is part of the Magcat® series of steam reforming catalysts that are used for the conversion of off gas, natural gas and LPG feeds in steam reforming plants.

Magcat® ITS - Textured Catalyst is designed for use in the inlet section of a reformer tube where processing heavier feeds or with aggressive process conditions where carbon formation is prevalent.

The use of this promoted textured catalyst throughout the tube allows users to operate at standard conditions without fear of potash migration.

Magcat® OTS

Magcat® OTS is part of the series of steam reforming catalysts that are used for the conversion of off gas, natural gas and LPG feeds in steam reforming plants.

Magcat® OTS - textured catalyst is designed for use in the outlet section of a reformer tube where processing methane rich feeds. The use of this non-promoted, textured catalyst allows nickel crystallites to be evenly distributed and highly active for steam reforming and close ATE.

DRI

Magcat® INS

Inert textured sphere proprietary magnesium aluminate spinel-based catalyst carrier

Available in various size options to allow optimised catalyst loading combination for the activity, heat transfer, pressure drop and pellet strength in each zone of the tube

Operational benefits:

- Compatible with all existing DRI reforming applications

- Extended catalyst life with potential to equal tube life in some applications

- Significantly lower catalyst cost per volume of gas reformed

- Fewer catalyst change outs required

- Increased reforming efficiency based on a combination of activity, heat transfer and pressure drop benefits suited to the application

- Elimination of downstream corrosion and fouling issues associated with some conventional potassium promoted catalysts

Magcat® ITS

Magcat® ITS is part of the Magcat® series of steam reforming catalysts that are used for the conversion of off gas, natural gas and LPG feeds in steam reforming plants.

Magcat® ITS - Textured Catalyst is designed for use in the inlet section of a reformer tube where processing heavier feeds or with aggressive process conditions where carbon formation is prevalent.

The use of this promoted textured catalyst throughout the tube allows users to operate at standard conditions without fear of potash migration.

Magcat® OTS

Magcat® OTS is part of the series of steam reforming catalysts that are used for the conversion of off gas, natural gas and LPG feeds in steam reforming plants.

Magcat® OTS - textured catalyst is designed for use in the outlet section of a reformer tube where processing methane rich feeds. The use of this non-promoted, textured catalyst allows nickel crystallites to be evenly distributed and highly active for steam reforming and close ATE.